Providing full-line solutions

for the manufacturing of high-speed cylindrical secondary battery equipment and next-generation supercapacitor equipment

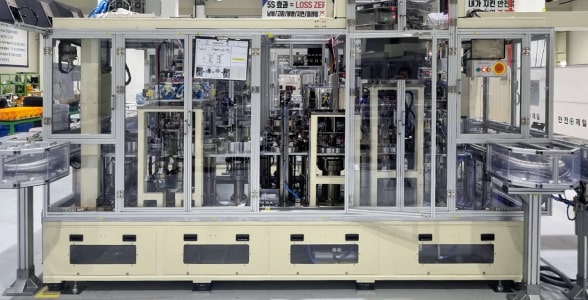

Cylindrical Equipment Solution

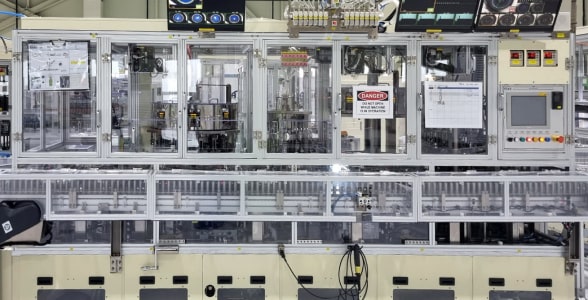

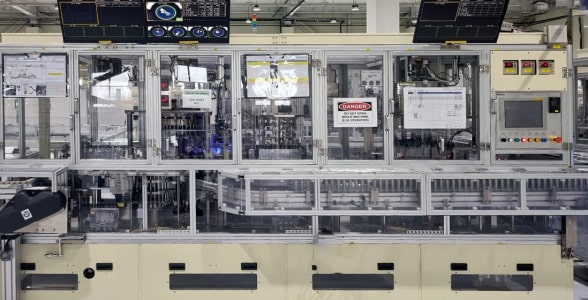

Cylindrical(18650, 21700) Assembly IN LINE

(J/R ATC ~ IR OCV)

Equipment developments for new cylindrical products 32700, 46800, 46 Series

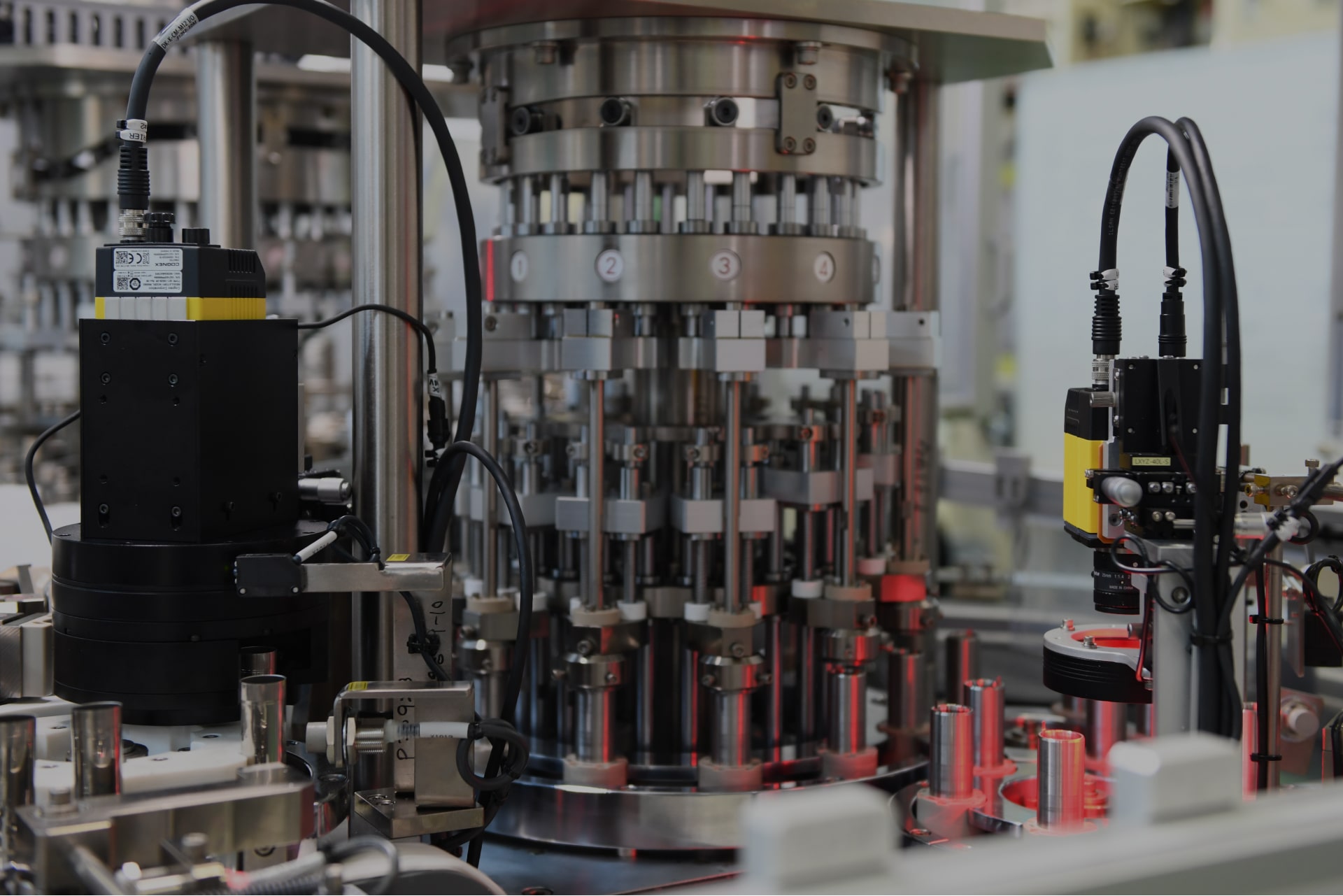

Equipment Features

Production Tact time: 150ppm, 220ppm, 300ppm, 350ppm

Length of equipment: 90m x 8m

Length of equipment: 90m x 8m

Application Field

Cordless vacuum cleaners, cordless power tools, electric vehicles, other mobilities

46 pi battery technology

46800,46950,46105,46120 Battery

- Improved energy capacity and output

- Increase productivity by reducing the number of processes per energy

- Increased price competitiveness

- Suitable for next-generation micro-mobility market

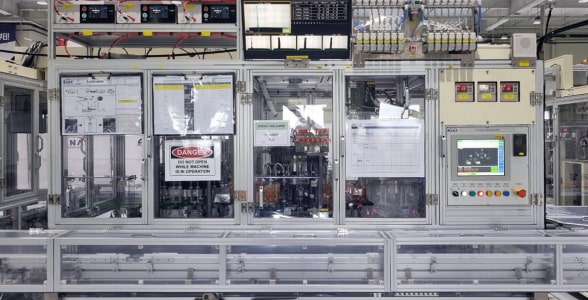

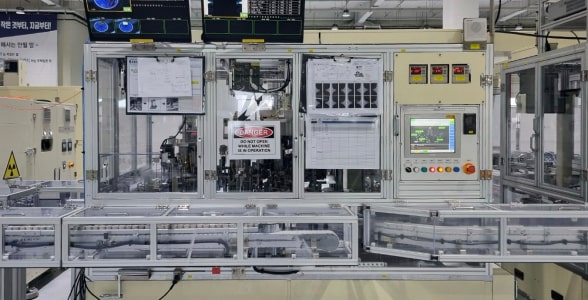

High speed automated assembly equipment

for the manufacturing of high-speed cylindrical secondary battery equipment and next-generation supercapacitor equipment

PROCESS 01

J/R Loader

- Type - TRANSFER

- Size - 2,200 X 2,730 X 2,280

- User Preparation - Material: J/R, J/R Tray, Tary Moving Cart

OPTION – B/I Blanking

PROCESS 02

B/I Inserting

- Type - INDEX

- Size - 2,500 X 1300 X 1,730

- User Preparation - Material: B/I Reel, Dust Collector: 1set

PROCESS 03

Can Loader

- Type - TRANSFER

- Size - 2,200 X 2,730 X 2,280

OPTION – Can Laser Marking

PROCESS 04

Can Inspection

- Type - ROTARY

- Size - 1,300 X 1,000 X 1,600

PROCESS 05

Can Inserting

- Type - ROTARY

- Size - 2,800 X 1,500 X 2,000

- User Preparation - Dust Collector: 1set

PROCESS 06

(-)Tab Welding & Swage

(-)Tab Welding

- Type - ROTARY

- Size - 3,850 X 1,250 X 2,800

- User Preparation - Dust Collector: 2set

Swage

- Type - ROTARY

- Size - 2,450 X 1,250 X 2,000

- User Preparation - Dust Collector: 1set

PROCESS 07

T/I Inserting & Hi-Pot Check

T/I Inserting

- Type - ROTARY

- Size - 2,320 X 1,500 X 2,300

- User Preparation - Material: C/P, B/I Reel, Dust Collector: 1set

Hi-Pot Check

- Type - ROTARY

- Size - 1,400 X 1,000 X 2,000

- User Preparation - Chroma 19073: 6

PROCESS 08

Beading

- Type - ROTARY

- Size - 2,300 X 1,650 X 1,900

- User Preparation - Dust Collector: 1set

PROCESS 09

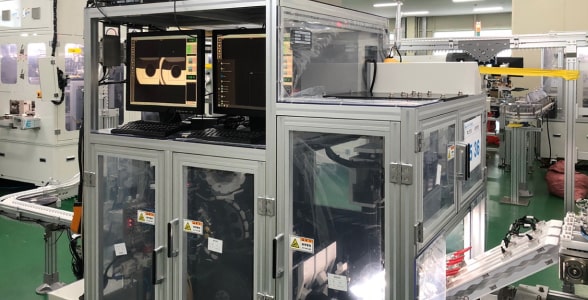

X-Ray Inspection

- Type - INDEX

- Size - 2,500 X 1,300 X 1,900

PROCESS 10

EL Filling

- Type - CHAMBER, TRANSFER

- Size - 1,0600 X 5,500X 2,050

- User Preparation - Material: Electrolyte,DMC,E/L Main Tank&Pipe

PROCESS 11

(+) Tab Welding

- Type - INDEX

- Size - 5,700 X 1,520 X 2,000

- User Preparation - Material: Top Cap Assy, Welding Fume Collector

OPTION – Leak Tester

PROCESS 12

Crimping & Sizing

- Type - ROTARY

- Size - 3,580 X 1,160 X 2,600

- User Preparation - Material: DMC, Dust Collector: 1set

PROCESS 13

Washing

- Type - INDEX

- Size - 5,240 X 2,430 X 1,800

PROCESS 14

Appearance Checking

- Type - ROTARY

- Size - 1,530 X 1,200 X 1,650

PROCESS 15

Lot Marking

- Type - ROTARY

- Size - 3,260 X 1,100 X 1,500

PROCESS 16

IR OCV & Pre Charging

- Type - TRANSFER

- Size - 3,260 X 1,100 X 1,500

- User Preparation - Tray, Tray Moving Cart

World’s highest cell operation rate for cylindrical assembly equipment.

JUNGDO Technology possesses every cylindrical high speed equipment’s core manufacture technology based on rotary, which are highly complex. JUNGDO Technology maintain competitiveness in design, processing, assembly and trial. We are also dedicating all our efforts to the development of equipment of our new product lines such as 32700 and 48600 series and beyond.